Corrugated vs Non-Corrugated Pizza Boxes: What’s Right for Your Menu?

Choosing the right pizza box can make or break your food presentation, customer experience, and even your delivery success. For commercial food operators in New Zealand, the debate often comes down to corrugated vs non-corrugated pizza boxes. Which is better for your menu, and how do you decide?

In this blog, we break down the pros and cons of each packaging type, compare materials, and help you align your box choice with your pizza size, crust style, and delivery method—while meeting hygiene standards and sustainability goals.

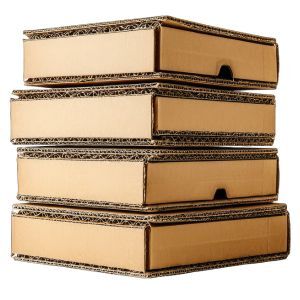

What Are Corrugated Pizza Boxes?

Corrugated pizza boxes are made from layered cardboard with a fluted (wavy) inner layer sandwiched between two flat liners. This structure adds:

-

Strength

-

Insulation

-

Resistance to crushing

Pros:

-

Superior insulation: Keeps pizza hotter for longer.

-

Stackable strength: Won’t collapse under pressure during transport.

-

Grease-resistant options: Many come with coated or lined interiors.

-

Recyclable & compostable: Especially if made with FSC-certified materials.

Cons:

-

More expensive: Cost per unit is higher.

-

Bulkier: Takes up more storage space.

-

Longer manufacturing lead time: For custom prints or sizes.

What Are Non-Corrugated Pizza Boxes?

Non-corrugated boxes are typically made from a single layer of paperboard or chipboard. They are thinner and less rigid, but still used in certain applications.

Pros:

-

Lightweight and compact: Easier to store and transport.

-

Cheaper: Lower cost per unit.

-

Good for short-term use: Ideal for single slices, flatbreads, or in-house dining.

-

Printable surface: Smooth surface makes branding easier.

Cons:

-

Poor heat retention: Not ideal for longer delivery times.

-

Easier to crush or bend: Less structural strength.

-

Higher grease risk: Often lacks proper liner.

Corrugated vs Non-Corrugated: Which Should You Choose?

Factor |

Corrugated Boxes |

Non-Corrugated Boxes |

|

Heat Retention |

Excellent |

Poor |

|

Strength |

High |

Low |

|

Best Use |

Delivery, Catering, Large Pizzas |

Slices, Dine-in, Budget Menus |

|

Grease Resistance |

Optional Liners Available |

Often Not Included |

|

Branding |

Moderate (depending on flute) |

High-quality print surface |

|

Cost |

Higher |

Lower |

Matching Your Menu to the Right Box

Choose Corrugated If:

-

You offer deep dish or heavy toppings

-

Your focus is delivery or takeaway

-

You serve family-sized pizzas

-

You need thermal insulation

Choose Non-Corrugated If:

-

You serve slices or small pizzas

-

Your business is event-based or short-term

-

You're focused on cost reduction

-

You offer dine-in or quick takeaway

FAQ – Corrugated vs Non-Corrugated Boxes

Are corrugated boxes recyclable?

Yes, especially if they’re not contaminated with grease or printed with non-recyclable inks.

Can I print on corrugated boxes?

Yes, but print quality is sharper on flat, non-corrugated surfaces. Many businesses use branded stickers instead.

Are non-corrugated boxes food-safe?

They can be, but check for food-grade certification and whether they include a grease barrier.

Can I use non-corrugated boxes for delivery?

Only for short distances or quick-service pizzas. For longer delivery times, corrugated boxes are more reliable.

Final Thoughts

The choice between corrugated and non-corrugated pizza boxes depends on your menu, service model, and budget. Corrugated boxes offer better performance for delivery and high-volume orders, while non-corrugated options are lightweight, cost-effective, and suited to quick-serve or dine-in formats.

At Insinc Products, we supply both corrugated and non-corrugated pizza boxes to suit all types of commercial food businesses across New Zealand. Contact us for samples, bulk pricing, and guidance on the best packaging for your operation.

Posted: Friday 12 September 2025